Our Kitchens

We believe food should be cooked not processed, so we have kitchens not factories, full of talented people not robots. It takes dozens of teams working day and night in harmony to create a COOK meal. From pudding chefs to vegetable prep, pastry making to washing up, it’s a remarkable team effort.

Kitchen Tour

1. Goods In

We check in all our ingredients with the same diligence as a sergeant major inspecting his troops on the parade ground. No ingredient enters the Kitchen unless we’re 100% happy and, as our suppliers will tell you, we are very, very fussy.

2. Prep

Under the watchful eye of Big Rob, the Prep Team prepares all the ingredients for the chefs. Vegetables are topped and tailed, peeled and sliced. Meat is trimmed and diced. In the Spice Room, herbs and spices are mixed for marinades. It’s where we roll our meatballs by hand - more than 4,000 in one go. And it’s where we marinate our meat for anything up to 24 hours, to ensure it’s tender and flavoursome.

3. Chefs

While every COOK dish is most definitely a team effort, it’s the chef who takes the glory and gets their name on the label. To cook many of our dishes we use big, steam-heated saucepans called bratt pans. In these pans, our chefs brown onions; make sauces and reductions; and slow-cook our casseroles for anything up to six hours. They need to season and taste every dish to make sure the flavour is just right.

4. Finishing

Finishing is where the final dish gets put together in the tray. Most food companies would use machinery to do this – for example, to squirt out just the right amount of sauce. But we believe people can do a more thorough and detailed job, with real care that makes a difference to the look and taste of the meal you serve at home. Assembling a dish can be very simple – ladling the right amount of Chilli con Carne into a tray – or involve as many as eight different processes. Laborious, but worth it.

5. Pastry

Our team of pastry chefs is led by Debbie. Her and her team have decades of experience of working with pastry and they prepare all of our shortcrust by hand, along with our sponge mixes, crumbles and quiche bases.

6. Packaging

There is no point in having great tasting food if it is not packed and labelled correctly. Miles heads up the Packing and Labelling team to make sure this all happens smoothly.

7. Puddings

Not long after Edward and Dale started COOK, they discovered some phenomenal frozen puddings in a farm shop in Redhill. Ed tracked down their creator: a local lady called Liz Dove, who was making them in the garage of her suburban home. She agreed to supply our little shops in Farnham and Tunbridge Wells and was soon making her puds exclusively for COOK. In 2003, she moved to a farm in Somerset, setting up her puddings kitchen in a converted cow shed.We opened the purpose- built COOK Puddings in 2015 in the nearby village of Ilton. It’s like Willy Wonka’s chocolate factory, but without Oompa Loompas (we’re working on it...)

Food Waste

Keeping food waste to a minimum not only makes good business sense, but it’s the right thing to do. Unfortunately, no matter how careful we are at our kitchens, there are inevitably some leftovers. Here’s what we’re doing about it.

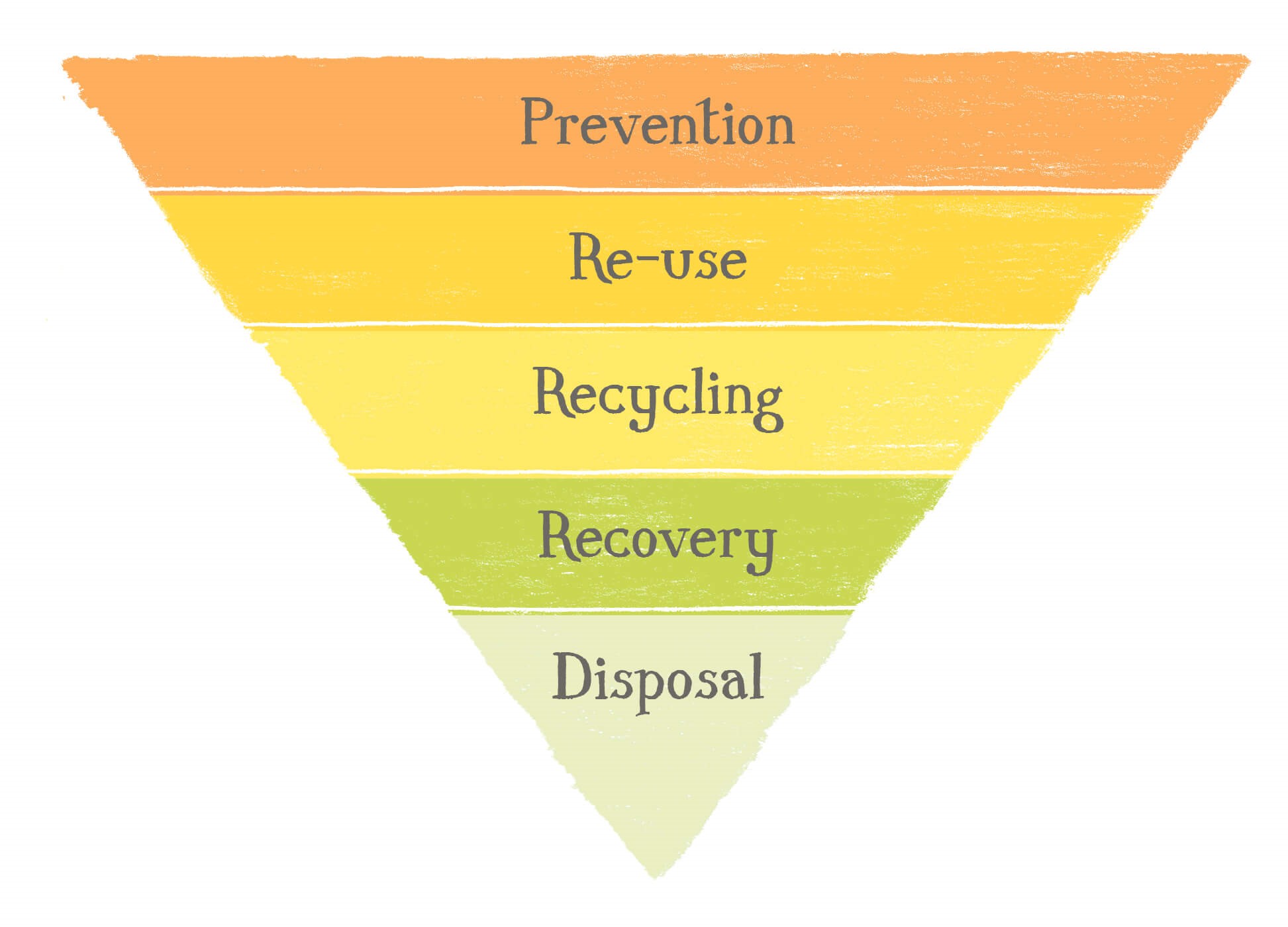

1. The Waste Hierarchy

This inverted triangle ranks waste management options according to what would be best for the environment.We see it as a good place to start when working out how to tackle our food waste.

2. Prevention

The big advantage of frozen food is it is less likely to be wasted by going off. Our products have use-by dates as long as nine months and so are less likely to be thrown away at home.

We are constantly seeking ways to prevent food waste at our kitchens. We are trying to better measure and then reduce the amount of food wasted in our Kitchens and our logistics centre. Our current goal is that less than 1% of all the food we handled ends up as edible food waste.

3. Re-use & Redistribute

Cooking by hand means we are often left with ingredients and excess meals at our kitchen that could be used for other purposes. We are working on ways for more of our leftovers to be used in staff lunches or redistributed, through partners such as FareShare, to charities helping to bring people together over good food.

In 2012 we started sending food to a local charity, Caring Hands. We continue to do so where possible, these days sharing excess meals. Also, on the rare occasion that the meals our chefs cook in our kitchen don’t hit our high standards we will sell these at a discounted rate in our stores as chef’s mistakes.

4. Recycling & Recovering

We currently have a system in place called the Rothenberg that captures and stores food waste from our kitchens. This food waste is then collected to be used in a process call anaerobic digestion, this creates a nutrient rich bio-fertilizer for farming and renewable energy that is exported to the National Grid.